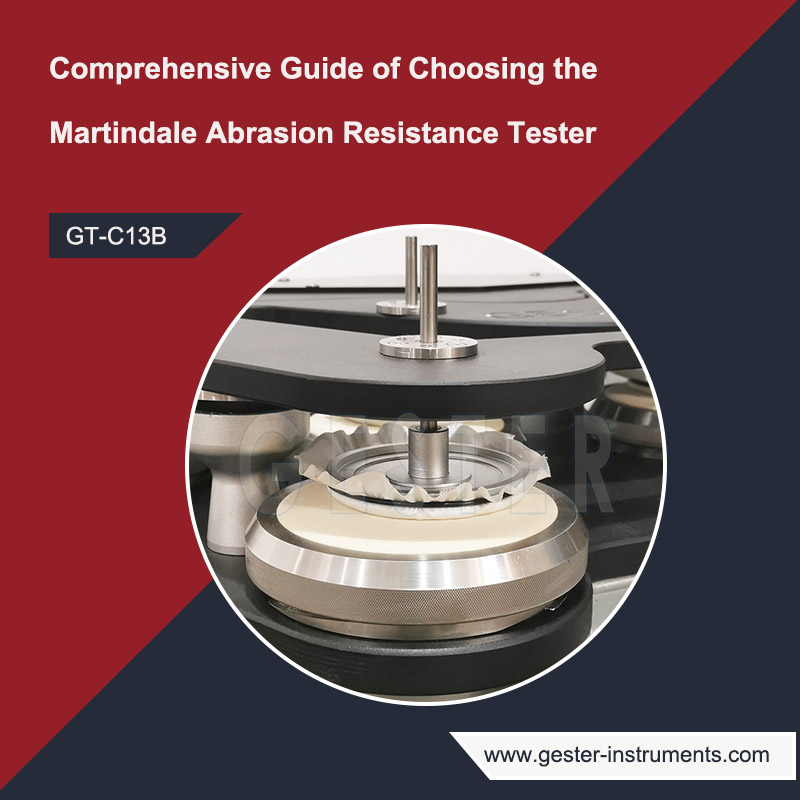

Comprehensive Guide of Choosing the Martindale Abrasion Resistance Tester GT-C13B

July 20, 2024

Comprehensive Guide of Choosing the Martindale Abrasion Resistance Tester In the textile and leather industries, abrasion resistance and pilling resistance are crucial indicators of material quality and durability. The martindale sbrasion tesistance tester is renowned for its precision and reliability, making it a popular choice in laboratories and quality control departments worldwide. This guide delves into the applications, standards, and unique features of the martindale sbrasion tesistance tester, providing a comprehensive overview to help you make an informed decision. Applications of the Martindale Tester The martindale sbrasion tesistance tester is the standard method for assessing the wear resistance and pilling tendency of textiles and leather. During the test, samples are rubbed against known abradents under low pressure, with the rubbing direction continuously changing. The degree of abrasion or pilling is then compared against standard parameters. This testing method is versatile, suitable for a wide range of materials, including textiles, socks, leather, coated upholstery, carpets, wood, and shirt collars. Through this process, materials can be accurately evaluated for their performance in real-world use, providing reliable data for research and quality control. Available Models The martindale sbrasion tesistance tester comes in four models, equipped with 4, 6, 8, and 9 abrading tables, respectively, to meet various testing needs. This flexibility makes it an ideal choice for laboratories and quality control departments, enabling efficient testing of diverse samples. Whether for small-scale experiments or large-scale testing, users can select the appropriate model based on their specific requirements, ensuring the precision and reliability of the tests. Martindale Abrasion Testing Standards The martindale sbrasion tesistance tester adheres to multiple international and national standards for abrasion and pilling testing: Abrasion: GB/T 21196.2, GB/T 13775, ISO 12947, ASTM D4966, IWS TM 112, M&S P19, Next 18, SN 198529, TWC 112, JIS L1096 (ISO17076-2 ball plate method, optional) Pilling: GB/T 4802.2, ISO12945-2, ASTM D4970, IWS TM 196, M&S P17, Next TM26, SN 198525 These standards ensure the reliability and comparability of test results, making the martindale sbrasion tesistance tester widely applicable in global quality control and research. By adhering to these standards, users can guarantee that their test results are internationally recognized and authoritative, providing robust assurance of product quality. Features of the Martindale Tester GT-C13B The martindale sbrasion tesistance tester boasts several outstanding features that set it apart in abrasion and pilling testing: 1. Testing Standard: Utilizes Lissajous figures for precise results. 2. Working Positions: Offers options with 4, 6, 8, or 9 abrading tables to meet various testing needs. 3. Counting Methods: Supports both count-up and count-down modes for ease of o...

View More