How to Conduct Liquid Strike-Through Tester

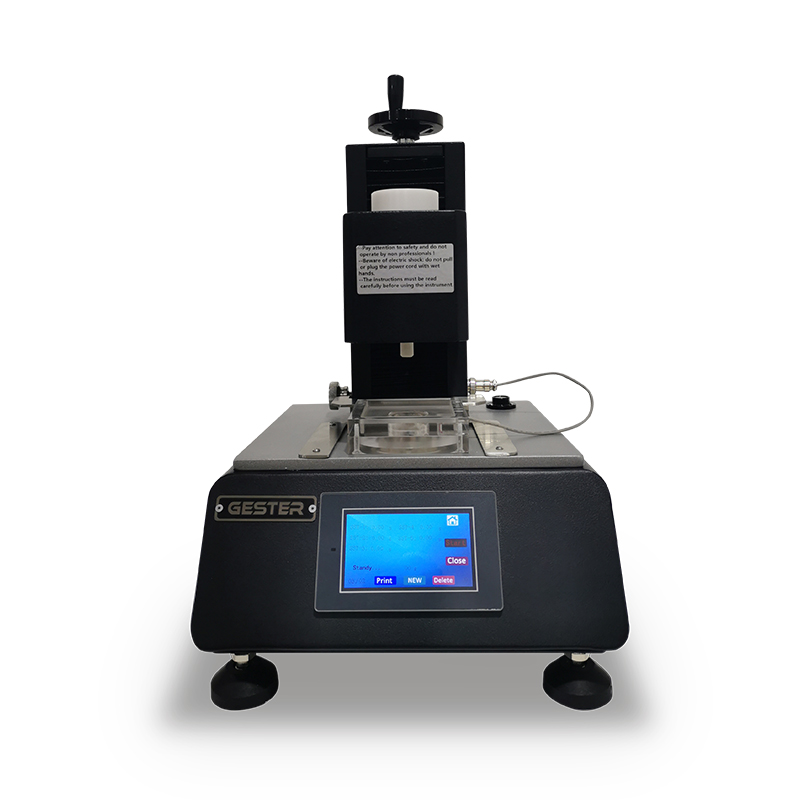

This Liquid Strike-Through Tester GT-CN04 measures the strike-through time of liquids through nonwoven materials, commonly used in products like diapers, sanitary napkins, and other absorbent hygiene products. It determines how efficiently a liquid can pass through a fabric layer, which is critical in ensuring the material's quality and performance.

This article will walk you through the essential steps to operate the GT-CN04 effectively, covering its applications, features, and a detailed guide on how to conduct the test.

Understanding the Application

The Liquid Strike-Through Tester GT-CN04 is primarily used to assess the liquid strike-through time of nonwoven materials. This test simulates the absorption of fluids through fabrics, mimicking real-world applications such as the use of diapers or sanitary products. The strike-through time is the period a liquid takes to penetrate the surface of the fabric.

The machine complies with international standards such as ISO 9073-13, GB/T 24218.8, and several others, ensuring accuracy and repeatability in results.

Features of the Liquid Strike-Through Tester GT-CN04

The Liquid Strike-Through Tester comes equipped with several advanced features designed for ease of use and precision in testing:

1. Color Touchscreen Control: This feature allows the operator to navigate easily through test options in both Chinese and English, making it user-friendly for a global audience.

2. Built-in Thermal Printer: After each test, results are printed instantly for quick reference.

3. Plexiglass Penetration Disc: The penetration disc, made of special plexiglass, is corrosion-resistant and durable, ensuring longevity.

Data Accessibility: All test results and statistical data can be stored and accessed from the machine's internal memory, providing a robust record-keeping system.

4. Positioning Device: A positioning device helps ensure the penetration disc is correctly aligned with the sample, reducing errors caused by misalignment.

Step-by-Step Guide to Conducting the Test

Let’s now dive into the process of conducting a liquid strike-through test using the Liquid Strike-Through Tester. This guide will cover everything from preparing the machine to viewing and printing the test results.

1. Preparing the Sample

Load the sample: Begin by placing the baseplate on the testing area of the machine. On top of the baseplate, stack absorbent paper (measuring 125mm x 125mm) with a total thickness of 4.5mm. This absorbent layer will help simulate the absorption characteristics of real-world materials. On top of the absorbent paper, place the test sample (also 125mm x 125mm in size).

2. Connecting the Penetration Plate

Attach the aviation plug: Connect the aviation plug to the penetration plate. Once connected, place the penetration plate into the slot above the sample, ensuring it fits snugly. This plate will apply pressure during the test and measure the liquid strike-through time.

3. Adjusting the Funnel Height

Set the funnel distance: Rotate the handle located at the top of the machine to adjust the funnel height. The funnel tip should be positioned 30mm above the sample (equal to the thickness of the penetration plate). This distance ensures consistent liquid flow during the test.

4. Powering the Machine

Turn on the power switch: After completing the mechanical setup, turn on the machine. You will be greeted by the color touchscreen interface where the test parameters can be configured.

5. Setting the Test Parameters

Set the interval time: This is the time between each penetration, ranging from 20 to 99 seconds. The time you choose depends on the specific test requirements.

Set the number of penetrations: You can configure the machine to conduct between 1 to 5 penetration cycles. This feature allows multiple tests to be conducted on the same sample, which is especially useful for understanding how the material performs over time under repeated exposure to liquid.

6. Preparing the Solution

Add the test solution: Prepare a test solution consisting of 2000ml distilled water and 18±0.01g NaCl. Ensure the solution has a surface tension of 70±3mN/m, which is critical for accurate results. Use a minim pipette to measure out exactly 5ml of solution and add it to the funnel at the top of the machine.

7. Starting the Test

Begin the test: Once you’ve set all the parameters, press the "Enter" button to begin the test. The machine will initiate the first penetration cycle, and the liquid will start to flow through the sample.

8. Conducting Multiple Penetration Cycles

Monitor the intervals: After the first penetration, the machine will count down the interval time before initiating the next cycle. During this interval, add another 5ml of solution to the funnel. Repeat this process for each additional penetration cycle (if configured for more than one).

9. Completing the Test

Test conclusion: Once the final cycle is complete, the machine will automatically stop. You can view the test results on the touchscreen display. The results will show the strike-through times for each cycle.

10. Printing the Results

Print the report: After completing the test, click on the "Print" button to generate a hard copy of the test results using the built-in thermal printer. This allows for quick documentation and comparison with other test results.

By mastering the use of this Liquid Strike-Through Tester, you can contribute to the development of higher-performing products that meet the needs of end-users, ensuring comfort, reliability, and safety.