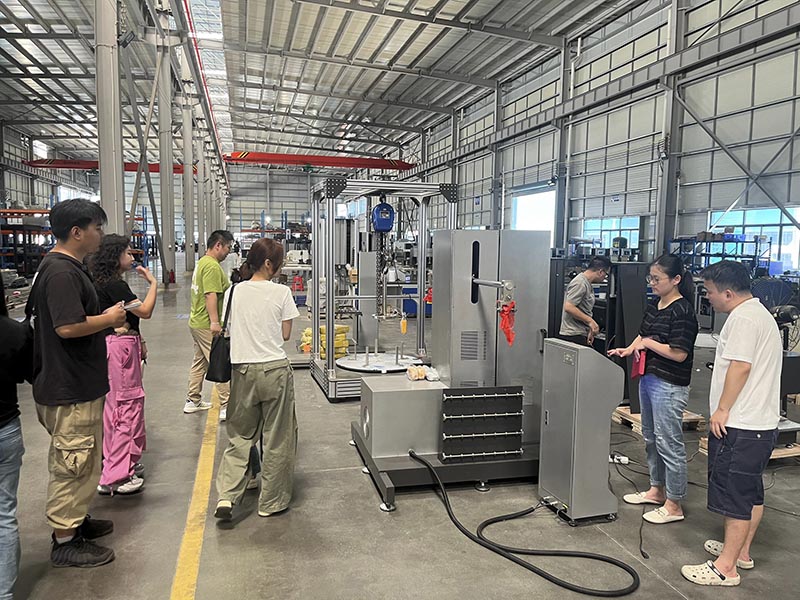

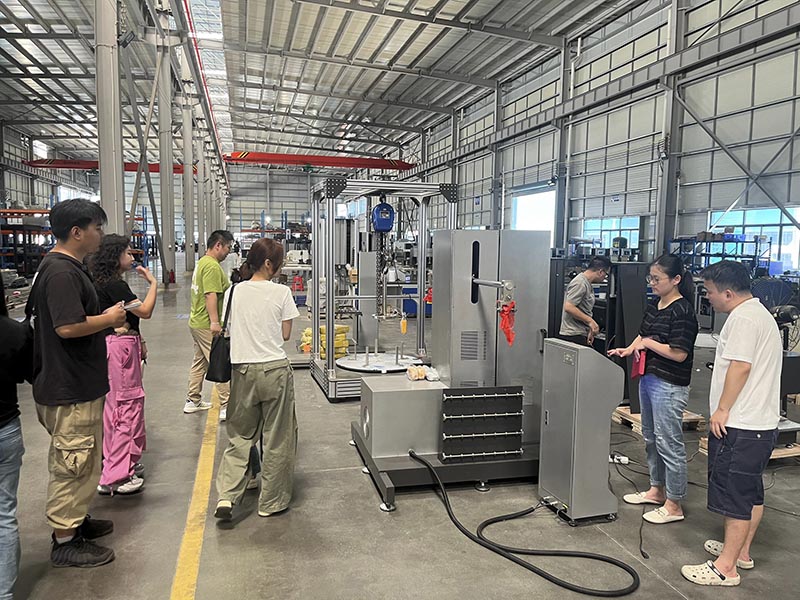

GESTER Conducts Employee Training on Multiple Testing Machines

To further enhance service quality, GESTER has recently organized a series of employee training sessions focused on multiple testing machines. These training sessions aim to improve employees' proficiency and understanding of the equipment, ensuring that each machine performs optimally in actual use, thereby better serving our customers. The training covered machines including the Protective Clothing Against Molten Metal Tester GT-C94, Luggage Caster Mileage Tester GT-LC01, Chair Swivel And Castors Durability Testing Machine GT-LB07, Chair Seating And Back Testing Machine GT-LB04-1, Chair Armrest And Seat Front Edge Testing Machine GT-LB03S, Chair Seating Impact And Durability Testing Machine GT-LB05, Chair Sideways Testing Machine GT-LB12, and BIFMA X5.1 Lounger Stability Testing Machine GT-LB06B.

Detailed Explanation of Training Equipment

1. Protective Clothing Against Molten Metal Tester GT-C94

It is used to determine the impact performance of high-temperature metal melt droplets in protective clothing and the high-temperature protection performance of textiles.

2. Luggage Caster Mileage Tester GT-LC01

The Luggage Mileage Tester is designed for road pilot testing of luggage with wheels, traveling bags, wheels, and wheel axles. The mileage tester can test the abrasion capacity of wheel material and the deformation and damage of the suitcase structure. The test result can be a reference for improvement. The training covered the equipment's structural principles, operating methods, and testing standards.

3. Chair Swivel And Castors Durability Testing Machine GT-LB07

The Chair Testing Machine applies to test all chair types with a swivel seat or with castors. In the training, employees learned in detail about the machine's swivel testing system and castor durability testing modules, including how to adjust swivel angles and load parameters. Through repeated practical exercises, employees mastered the equipment's usage methods, ensuring reliable results from each test.

4. Chair Seating And Back Testing Machine GT-LB04-1

The Chair tester tests the strength and durability of the seats and backrests by simulating the routine use loading of the seat. The training content included an introduction to the machine's various components, such as the seat durability testing module and back pressure sensors.

5. Chair Armrest And Seat Front Edge Testing Machine GT-LB03S

The Chair Testing Machine tests the strength and durability of the handrails, seats, or other parts by simulating the loading of the seats during routine use. Employees learned about the machine's working principles, operating procedures, and common troubleshooting methods.

6. Chair Seating Impact And Durability Testing Machine GT-LB05

This Chair Seating Impact and Durability Testing Machine applies to all types of chairs, with two functions: chair seating impact and seating durability tests. The purpose of this test is to evaluate the ability of the chair to withstand heavy and abusive impact forces on the seat and to evaluate the ability of chairs to withstand fatigue stresses and wear caused by downward vertical forces on the seat.

7. Chair Sideways Testing Machine GT-LB12

This test machine is used to simulate the loading conditions of the chair in daily use and to test the lateral static load strength of the handrail. The machine is equipped with two drive devices and can be individually controlled to repeatedly load the test points of the seat. Through different parameter settings, it can test different seats.

8. BIFMA X5.1 Lounger Stability Testing Machine GT-LB06B

This Chair Testing Machine is suitable for testing seat, office chair, and lounger stability. Through practical operation, employees learned how to set testing conditions and conduct effective stability tests, ensuring that products meet international standards.

Maintenance and Troubleshooting

The training also emphasized the maintenance and troubleshooting of the equipment. Professional instructors explained how to perform daily maintenance, including cleaning, lubrication, and inspecting key components of the equipment. The training also provided detailed troubleshooting steps and solutions for possible issues. This part of the training ensures employees can not only operate the equipment but also extend its service life and ensure long-term stable operation.

Training Outcomes and Future Outlook

Through this systematic training, GESTER employees have not only fully mastered the operational skills of multiple testing machines but also enhanced their deep understanding of the equipment's working principles. This will help us perform equipment operations and tests more efficiently in the future, providing more professional and high-quality services to our customers.

Additionally, through repeated practical exercises during the training, employees have gained extensive practical experience, enabling them to solve problems encountered in actual operations more quickly. This combination of theory and practice has not only improved employees' technical levels but also boosted their confidence and enthusiasm for work.

In the future, GESTER will continue to adhere to the customer-centric service concept, regularly organize various equipment training and technical exchange activities, and ensure that employees' skills remain at the forefront of the industry. We believe that through continuous learning and improvement, GESTER will be able to provide better testing equipment and services, helping customers achieve greater success in their respective fields.