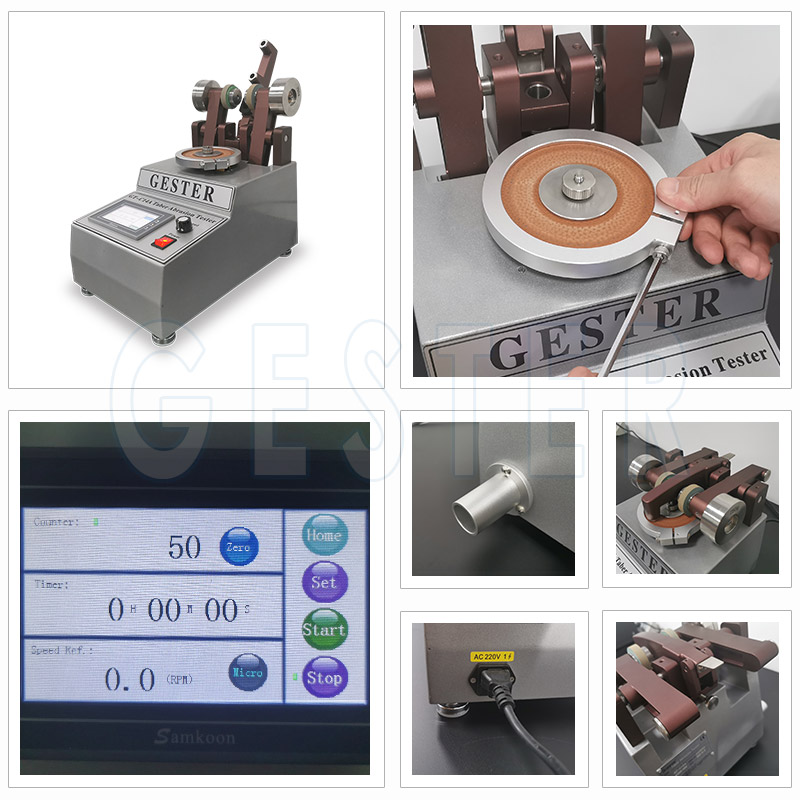

The US Taber Abrasion Resistance Tester (ASTM D3884 Abrasion Resistance of Textile Fabrics ) is used to interpret the wear resistance of metals, coatings, plate surfaces, coating materials, textiles, leather, and rubber, etc.

The first step, Calibrating wheels.

A: Rubber-base Wheels Calibration (eg. CS-10, CS-10F, CS-17)

(1) A new set of rubber-base wheels must be refaced twice for 50 cycles;

(2) If the used wheel is less than 1000 cycles before use, refaced 25 cycles or 50 cycles (recommended refaced 25 cycles); if it is greater than or equal to 1000 cycles, pre-refaced 50 cycles.

(3) For every 1000 cycles of the wheel during the test, 25 or 50 rotations must be refaced.

B: Vitrified-based wheels Calibration ( eg. H-10, H-18, H-22, H-38)

Not need to refacing unless the surface of the wheel is are marred or chipped; every 300 cycles, clean particles using an air hose durinf the test.

Sampling: 150mm*150mm, 5 pieces (actual sampling 100cm²), for samples with width less than 125mm, the entire width for samples is used.

The second part of the United States Taber Abrasion Tester, the specific operation:

1.Set the appropriate grinding wheel and load as required. Grind the fabric to a specific end point and record the final number of revolutions; the end point may include Pass/Fail criteria, such as: loss in breaking strength, yarn breakage, coating/gloss/gloss loss, appearance of pilling and other changes; if the customer Have their own requirements, according to customer requirements as the end.

2.Recording the number of sample rotations and take the average of 5 samples.

End point judgment:

Woven fabrics: break a single line

Non-woven: Frayed at least 0.5mm in diameter

Knitted fabric: 1 yarn broken, forming a hole

Fleece: Flue finish

references:

2007 and previous versions:

Grinding wheel: CS-10

Load:> 240g/m2, 500g/rev

≤ 240g/m2, 250g/rev

2009 Edition

According to use table

ASTM D3884: Test of Friction Wheels and Heavy Hammer Loads, 2009 Edition

Type of fabric Grinding wheel Load (g)

Textile fabrics ≥100g/m2<240g/m2(medium) CS-10 500

Textile Fabrics <100g/m2 (Lightweight) CS-10 250

Fleece CS-10 500

Coated fabric H-18 1000

Automotive Fabric CS-10 1000

Decorative fabric H-18 500

Textile Fabrics (Other) H-18 1000

Non-woven fabric H-10 (Temporarily absent) 250

Automotive Leather CS-10 1000

Dyed Leather CS-10 500

Other durable leather H-18 1000

Car carpet CS-10 1000

Carpet (wide) H-18 500

US Taber Abrasion Tester Principle: An "X" type of friction is created by the rotation of a pair of friction wheels.