In the world of material safety testing, ensuring the accuracy and reliability of results is critical. The Vertical Combustibility Tester GT-C35B is an advanced instrument designed to determine the flammability of vertically oriented fabrics, making it ideal for textiles, soft fabric toys, and protective clothing industries. To maximize the effectiveness of this tester, proper training is essential. This article outlines the process of training customers to use the Vertical Combustibility Tester GT-C35B, while emphasizing the importance of after-sales support to ensure consistent performance and long-term reliability.

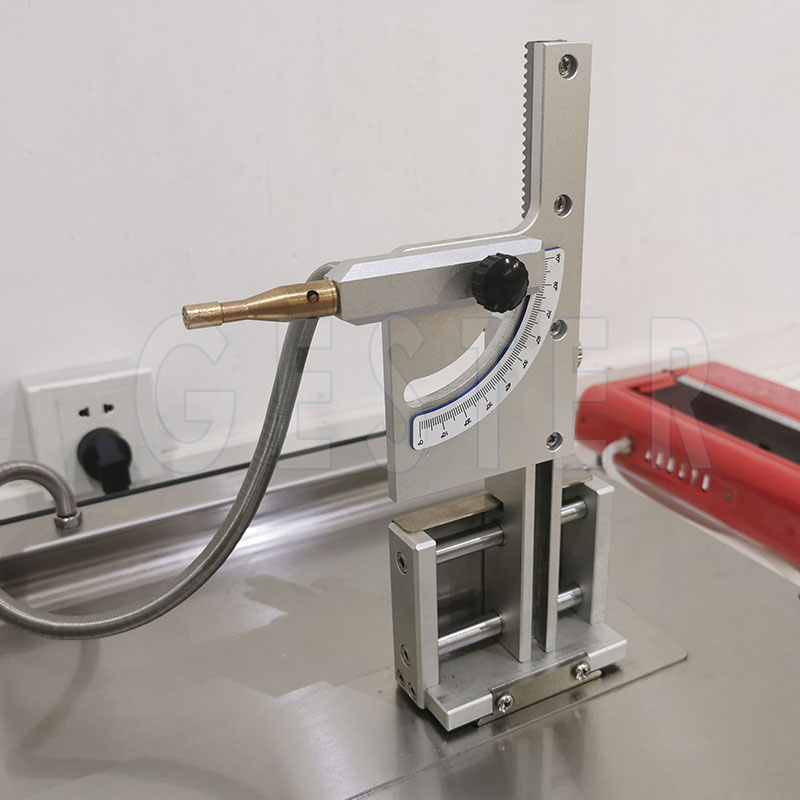

Providing customers with a comprehensive training program is crucial for the optimal use of the Vertical Combustibility Tester GT-C35B. This step-by-step guide ensures that the user can accurately conduct tests and interpret results effectively: